About Us

The art of

lighting wisely

Refined emotions

What we do

In our factory we produce high end lighting systems for yachting lighting, contract and interiors, to offer refined emotions through the beauty of the light.

Supports

How we work

BCM provides the customer with a highly qualified technical sales team. Upon request, our team works closely with designers to customize products from its collections, as well as in the design and production of bespoke items. Our team consists of

• Two commercial teams (Italy and Abroad)

• Engineering and design team

• Electronic and testing team

We support the customer at every stage of its realization in order to simplify the decision-making process and to get the best results as possible.

Our factory

MECHANICAL WORKS

We carry out extremely high precision machining thanks to a production department equipped with the latest generation machines.

• 6 multi-axis CNC automatic lathes.

• 4 vertical machining centers for simultaneous machining of up to 5 axes and integrated automatic system.

• Multi-axis machining.

• Swiss-type lathes for small parts.

STAMPING

We create different shapes of sheet metal parts thanks to 3 cold forming presses and we keep the molds over time in our factory.

WELDING

We use the oxy-acetylene welding process to ensure maximum craftsmanship in the creation of customized shapes and in small series.

POLISHING

In the polishing department we carry out a handcrafted process to obtain aesthetic finishes of a higher level, taking care of the individual creations one by one thanks to the skilful dexterity of expert operators. To complete the process, we use a degreasing and pickling system with automatic cycles with low environmental impact.

ELECTROPLATING

Inside our factory, thanks to our plating tanks, we carry out surface treatment for nickel plating, chrome plating and stainless steel passivation with low environmental impact (stainless steel passivation only).

PAINTING

At the end of the mechanical manufacturing processes, our painting department is spread over 3 different painting systems and 3 drying ovens to create different finishes simultaneously.

PICK & PLACE

We create the PCBs of our LED modules internally thanks to a “Pick & Place” assembly system complete with screen printer and relative oven.

ASSEMBLY AND PACKAGING

At the end of the production processes, the final stage of assembly and packaging is carried out using FSC cardboard packaging, reusing the old boxes to obtain cardboard sugared almonds and we only use recycled bubble wrap.

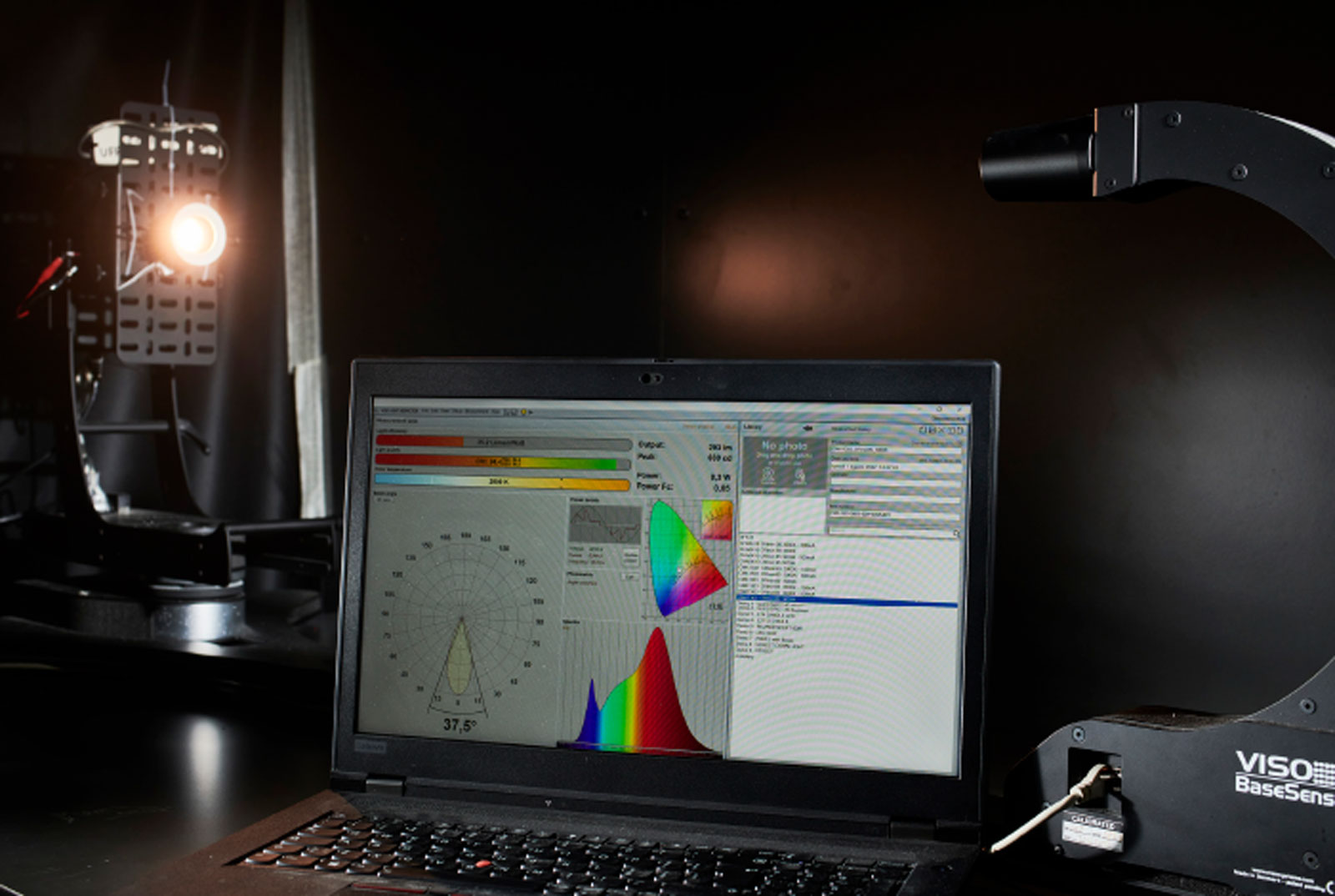

PHOTOMETRIC TESTING

In our laboratories we carry out photometric tests with a photogoniometer to guarantee the ideal performance of the LED sources used. We evaluate all photometric parameters in compliance with the latest performance standards (TM30)